How Much Does It Cost to Build a Wheelchair Ramp?

Typical Range:

$1,049 - $3,378

Typical Range:

$1,049 - $3,378

Cost data is based on actual project costs as reported by 799 HomeAdvisor members. Embed this data

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

•

•

•

•

Updated December 13, 2022

Written by HomeAdvisor.The cost of a wheelchair ramp, fully installed by a pro, falls between $1,049 and $3,378, with a national average of $2,209. Your wheelchair ramp installation cost will vary depending on the material, type, and local labor rates. On the low end, a short wheelchair ramp might cost $200, while a long ramp could reach $8,000 or more.

Ramps offer wheelchair users more accessibility, but only if constructed properly. Some can be difficult to use or even dangerous if installed improperly, so it’s important to hire a professional who’s experienced and familiar with the Americans with Disabilities Act (ADA) guidelines. Below, we’ll explore average wheelchair ramp prices and cost factors that can affect your total.

2022 Notice: Material Prices Are Surging

Demand for siding and other building materials has grown over the past year. And as a result, manufacturers are increasing materials prices. Prices have gone up 5% to 10% this year, and many parts of the country are experiencing long delivery times. If you're planning a building project, we recommend starting as early as possible in the season, preparing for potential price fluctuations, and allowing extra time to order materials.

Let's calculate cost data for you. Where are you located?

Where are you located?

| National Average | $2,209 |

| Typical Range | $1,049 - $3,378 |

| Low End - High End | $395 - $5,900 |

Cost data is based on actual project costs as reported by 799 HomeAdvisor members.

For a standard 24-linear foot wheelchair ramp, the ramp material, its size, and ramp type will account for most of the budget. Additional cost factors include any add-ons you want for your ramp, such as weight specifications, landings, handrails, where you want to place the ramp, or special features, like a stair lift.

See the estimated average percentages your factors contribute to your total cost.

The ramp material you choose can significantly increase the price. Rubber ramps are the most affordable, while steel ramps are the most expensive. Choose from concrete, wood, aluminum, prefabricated aluminum, or composite, depending on your budget and needs. The ramp material you choose significantly impacts the type of contractor required and the hourly labor rate.

Installing a wheelchair ramp costs, on average, $50 to $250 per linear foot, including material prices. It goes without saying that the longer and wider the wheelchair ramp, the more you’ll spend on materials and labor.

The type of ramp you have also affects your overall project total. For the budget-conscious, choose a mini ramp or portable ramp. On the other end of the spectrum are sturdier options, such as semi-permanent, modular, and permanent ramps.

When installing a wheelchair ramp, your budget will play a major role in determining how much you can get done. Whether you opt for a simple ramp to aid your or your family member’s accessibility requirements or you want a state-of-the-art metal ramp with special features, select the cost range that best suits your needs to get started.

Wheelchair ramp installation costs between $50 and $250 per linear foot, depending on the material, ramp type, and labor rates. The chosen material also significantly impacts the type of contractor required and thus the average hourly labor rate.

The table below explores typical wheelchair ramp lengths and what you can expect to pay for installation and materials:

| Wheelchair Ramp Length in Lin. Ft. | Average Price Range (Including Materials and Installation) |

|---|---|

| 4 | $200 – $1,000 |

| 8 | $400 – $2,000 |

| 12 | $600 – $3,000 |

| 16 | $800 – $4,000 |

| 20 | $1,000 – $5,000 |

| 24 | $1,200 – $6,000 |

| 28 | $1,400 – $7,000 |

| 32 | $1,600 – $8,000 |

The cost of a wheelchair ramp per linear foot may be as low as $50 for rubber or as high as $250 for concrete, wood, or steel. Review the table below to see how your chosen material can affect the overall cost of your wheelchair ramp.

| Wheelchair Ramp Material | Average Price Range per Lin. Ft. |

|---|---|

| Concrete | $200 – $250 |

| Wood | $100 – $250 |

| Aluminum | $150 – $200 |

| Steel/metal | $200 – $250 |

| Prefabricated aluminum | $100 – $150 |

| Rubber | $50 – $150 |

| Composite | $150 – $200 |

Concrete ramps cost around $200 to $250 per linear foot. Depending on your location, you may need to factor in a little more for labor costs of pouring concrete.

Concrete is ideal for a permanent wheelchair ramp because it’s rough and textured. However, concrete is one of the more expensive ramp materials and is difficult to remove.

Wheelchair ramps made of wood typically cost between $100 and $250 per linear foot to install. Installing a wood ramp is an easier DIY project and can be quite affordable if you opt for basic lumber.

However, wood ramps require weather protection and slip prevention for rain and snow. If you don’t regularly maintain a wooden wheelchair ramp, it can become unsafe over time due to warping or rot.

The average aluminum wheelchair ramp costs approximately $150 to $200 per linear foot. Aluminum is an excellent choice for a ramp because it's strong, lightweight, and resistant to corrosion. The grooved surfaces typically found on aluminum ramps help with traction in rainy and snowy conditions.

But this material can be expensive. If you go with more lightweight aluminum, it may dent and wobble over time.

At $200 to $250 per linear foot, steel is one of the most expensive wheelchair ramp materials and the most secure. Go with galvanized steel to avoid rust and corrosion, and make sure you get a ramp with a textured surface to prevent slippage.

Prefabricated aluminum ramps go for around $100 to $150 per linear foot, making them a great way to save money on wheelchair ramp installation costs. You’ll have to assemble the prefab sections yourself, and you’ll also need to plan around their extended lead time (the time it takes to manufacture and ship them).

Rubber wheelchair ramps cost about $50 to $150 per linear foot, so rubber is the way to go if you're building a wheelchair ramp on a budget. However, only consider rubber for small ramps, as its durability is low.

One major bonus: Rubber is naturally slip-resistant, making it a good choice for indoor shower ramps.

Composite wheelchair ramps range from $150 to $200 per linear foot. The biggest selling point of composite is that it’s moisture-resistant, meaning you don’t need to worry about it warping over time. You also don’t have to worry about rotting and insect damage. However, composite ramps can be more pricey.

The type of ramp can also impact the overall cost:

| Type of Ramp | Average Price Range |

|---|---|

| Mini | $100 – $200 |

| Portable | $100 – $2,000 |

| Modular | $400 – $5,000 |

| Semi-permanent | $350 – $2,000 |

| Permanent | $1,000 – $6,000 |

You can purchase a mini-ramp for just over $100. Mini ramps are typically 30 inches wide by 3 feet long and are designed to allow passage over a raised threshold or between split levels up to a height of about one stair step. Most are made of aluminum to make them lightweight and easy to transport.

Portable ramps are available in lengths of 3 feet to 10 feet and cost between $100 and $2,000, depending on the type. Typically used for getting into automobiles or slightly elevated entranceways, portable ramps can’t be used to access more than two vertical steps due to their limited length. For example, a 5-foot ramp can only rise 5 inches per ADA guidelines. Portable ramps can also be difficult to set up and take down without assistance.

These are common types of portable ramps and their general costs:

Folding: $100–$1,000; also called suitcase or multifold; one or more folds for portability

Roll-up: $300–$1,300; made of aluminum; can be rolled up for storage

Track: $250–$2,000; have two tracks that line up with the wheelchair; can be folded or opened to optimal length

Modular wheelchair ramp prices start as low as $400 but can reach $5,000 for longer models. They're prefabricated, meaning you or a contractor needs to assemble the pieces when they arrive. Modular ramps usually come in aluminum or steel and are generally low-maintenance. Assembly is easy, but it could be more difficult to install if you didn't calculate the measurements correctly before ordering.

Semi-permanent wheelchair ramps cost anywhere from $350 to $2,000 to install. Though they aren’t anchored to the ground permanently, they’re still stable and safe. If you don't need the ramp to stay in place for multiple years, a semi-permanent ramp can be a good option.

As the name suggests, permanent ramps (typically made of concrete, wood, or steel) are designed to stay in one location much longer. You might install permanent ramps, which cost between $1,000 and $6,000, at entry and exit points for a home if someone with a disability will live there permanently.

Additional cost factors can impact the overall price of wheelchair ramp installation. Read below to get more in-depth information.

Some ramps are designed for manual wheelchairs, while others are designed for heavier electric scooters or wheelchairs. Some ramps may only support the weight of an unoccupied wheelchair. In general, the stronger the ramp, the more expensive it’s likely to be.

All wheelchair ramps require flat landings at the top and bottom of the ramp. This allows doors to open smoothly and for people in wheelchairs to stop and rest on longer ramps.

For every 30 inches of rise, you need to install a landing. Additional landings beyond the top and bottom can increase the overall installation price.

Larger ramps require handrails and guards. For example, ramps that rise more than 6 inches or are greater than 6 feet in length require handrails on both sides.

Prefab kits may come with handrails, but if you or a contractor is building a ramp with raw materials like wood or metal, you’ll need to factor in additional costs for handrails.

If you’re building a ramp out of metal or wood, budget for additional materials to prevent slippage. You can get a 2-inch-by-60-inch roll of anti-slip grip tape for $15 to $35 at a local hardware store.

Check with your local building office before beginning your project to see if they require a permit. If so, expect to pay between $30 and $120 for the building permit cost. If you hire a contractor, they may handle the permit process for you.

The hourly labor rate for a professional wheelchair installer depends on the ramp you're building. For example, a wooden ramp will require a carpenter, but a concrete unit could require a mason.

Carpenters cost around $35–$100 per hour.

Hiring a mason for pathway installation costs around $1,800–$4,800 per project.

A handyperson costs around $60–$65 per hour.

Whichever contractor you hire should be licensed and familiar with ADA regulations.

The ramp location can often impact the price. Outdoor ramps require more durable materials and are often longer, while indoor ramps need to be shorter and more portable. A typical indoor ramp may range between $200 and $2,000, while an outdoor ramp generally costs $1,200 to $5,000.

Often, a wheelchair ramp installation makes up just one of many disability accommodation remodeling costs. Depending on your home and the nature of your needs, you may also need to budget for:

Stair lift costs: $2,000–$15,000

Elevator or chairlift installation costs: $2,550–$5,800

Doorway widening costs: $700–$2,500 per door

Before installing a ramp, familiarize yourself with the U.S. Access Board’s ADA requirements for wheelchair ramps. Although homeowners legally don’t need to comply with guidelines, meeting them is in the best interest of anyone in your home who uses a wheelchair.

Here are some critical points to keep in mind:

For every 1 inch in height, there should be 1 foot in length. This is the maximum slope permissible.

Ramps should be at least 36 inches wide.

Runs shouldn’t exceed 30 feet (30 inches in height) without a landing somewhere between the top and bottom.

The slope is the most critical safety concern when designing a ramp. For a permanent fixture, use the lowest slope possible, no more than 1 inch of rise per 1 foot of length.

To estimate the length needed, measure the height in inches and change the inches to feet. For example, a ramp that’ll rise 30 inches must be at least 30 feet, not including the landings.

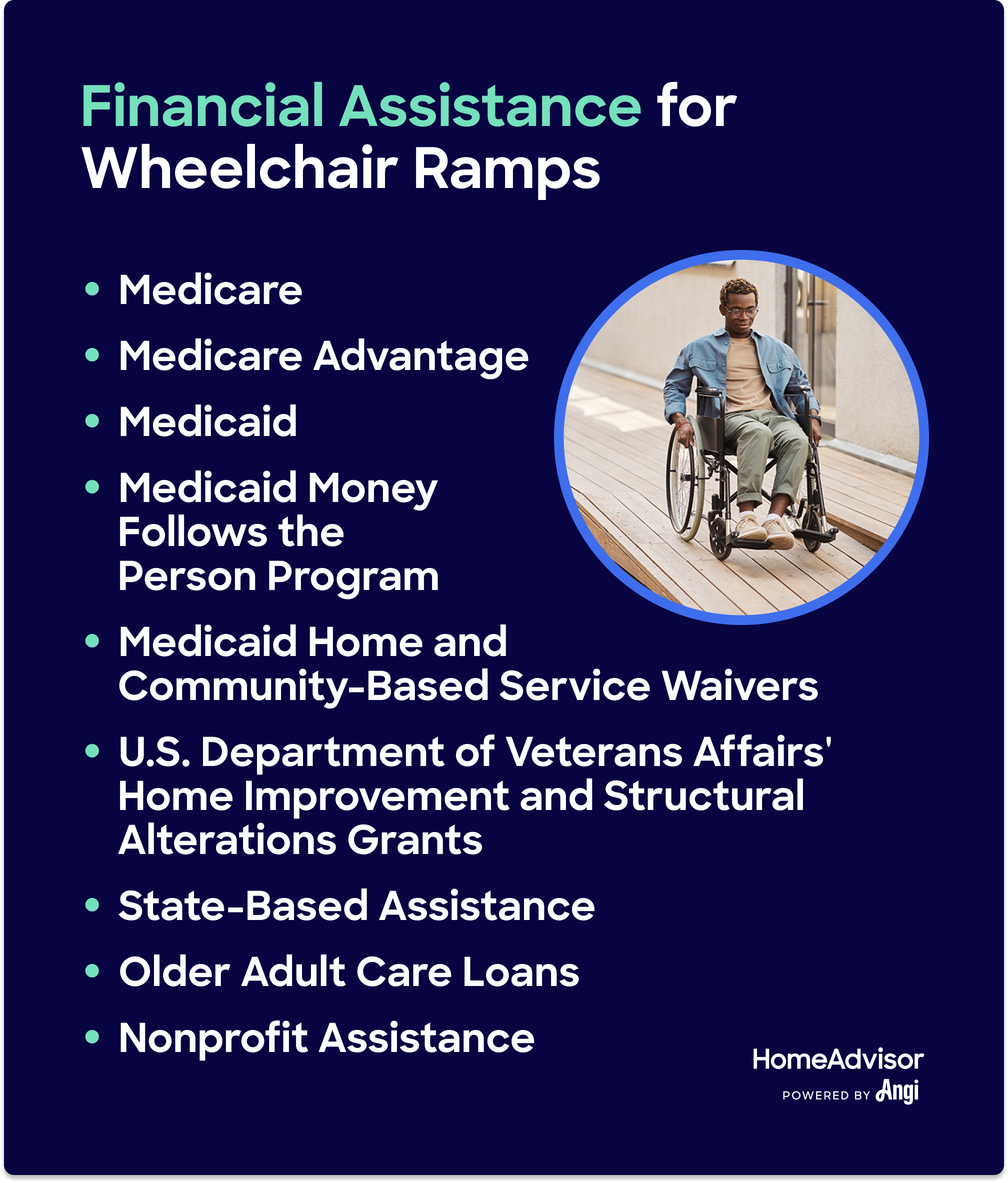

In some cases, financial assistance may be available for people with disabilities who need a permanent or modular unit.

According to Medicare policy, disability ramps are considered durable medical equipment (DME) and are fully reimbursable if used for medical purposes. However, a licensed physician will need to deem the structure medically necessary.

Alternatively, Medicare Advantage (MA) plans might cover wheelchair ramp costs for eligible people with certain chronic conditions, including Alzheimer's disease, rheumatoid arthritis, and metastatic cancer.

Medicaid is a federal program administered by the states, so policies vary. In many states, Medicaid follows the same guidelines as Medicare and will only reimburse the costs of a wheelchair ramp if it’s deemed medically necessary by a physician.

In some states, low-income older adults and people with disabilities can pursue assistance via standard Medicaid or Home and Community-Based Service Waivers (HCBS Waivers). With these, ramps are considered home modifications and are covered fully or partially.

Older people may also be qualified for the Money Follows the Person Program, which provides financial assistance for those transitioning from a nursing home to a personal residence that needs modifications. Again, this option isn't offered everywhere, so check availability with your state.

Veterans may qualify for the U.S. Department of Veterans Affairs Cash and Counseling benefit. Qualified veterans receive a care budget to select the necessary services and supplies. Any money spent outside of that budget is paid out of pocket.

Veterans may also be eligible for Home Improvement and Structural Alterations Grants (HISA Grants) from the VA. These grants are given to help make home modifications to improve accessibility. Those whose disabilities are military service-related may qualify for up to $6,800, while those with disabilities not related to their time served may receive up to $2,000.

Other financial assistance options include state-based assistance, older adult care loans, and nonprofit assistance. Their availability varies by location.

For short-term needs, wheelchair ramp rental costs between $100 and $280 per month. The initial installation will be a one-time charge of about $300 to $800. The cost of rental and installation will depend on the specific configuration needed. Typically, the longer the ramp, the higher the rates. Many rental companies will allow you to use a portion of the rental fee toward a future purchase if you need it permanently.

Building a wheelchair ramp yourself costs roughly $35 per linear foot, depending on your chosen material. Because you're likely building the ramp for a loved one with a disability, the work can have more meaning.

But make no mistake: Building a ramp is time-consuming and laborious. Simple mistakes can make for unsafe ramps or ramps that degrade over time. And wheelchair ramp repair costs are expensive—$1,130 on average. Building a modular ramp as a DIY project can avoid some of those pitfalls, but otherwise, it's advisable to leave ramp building to the pros.

When looking for a contractor to build a wheelchair ramp, make sure you hire a wheelchair ramp builder near you who's experienced in disability renovations. These experts are more experienced in designing and constructing wheelchair ramps and can ensure top levels of safety and accessibility. Contact at least three licensed contractors to ensure you're working with someone experienced in all aspects of your project and to get the best rate.