How Much Does It Cost to Install Shiplap?

Typical Range:

$500 - $7,500

Typical Range:

$500 - $7,500

Cost data is based on research by HomeAdvisor.

On average, shiplap interior installation costs around $1,000, with the cost ranging from $500 to $1,500 per room. Shiplap installation for the exterior of a home averages around $4,000—with a cost range between $2,800 and $7,500—depending on the project's scope. Shiplap, a durable form of siding that creates a specific design look, can be made from old wood or new materials. The main design feature of shiplap is rabbeting, or connectible grooves in the boards that overlap edges and create a solid joint.

Shiplap prices range from around $2.50 to $7 per square foot. The price of the boards differs based on the type of wood. While there are several types of wood that shiplap planks might come in on, many shiplap planks are available in redwood, cedar, ipe, fir, hemlock, spruce, poplar, pine, MDF, or fiber cement.

| Shiplap Type | Cost per Sq. Ft. | Cost of an Entire Exterior |

|---|---|---|

| Hardwood | $0.80 – $4.00 | $2,500 – $3,500 |

| Cedar | $2.50 – $7.00 | $2,500 – $7,000 |

| Pine | $2.50 – $4.00 | $2,500 – $4,000 |

For hardwood shiplap, homeowners can expect to pay between $0.80 and $4.00 per square foot. Hardwood is the most common type of shiplap and works on either the interior or exterior of a home. It’s unique because the term “hardwood” refers to any wood taken from broad-leafed trees, so the boards can come from several different types of trees.

The cost of cedar shiplap boards ranges from $2.50 to $7.00 per square foot, and the pricing varies depending on the quality of the cedar. Average cedar boards range from $2.50 to $5.00 per square foot, while higher quality cedar costs between $4.00 and $7.00 per square foot. You can install cedar on either the interior or the exterior of a home.

Pine is sold in 100-square-foot bundles for $275 to $375 per bundle, or roughly $2.50 to $4.00 per square foot. A standard material for exterior home siding, pine shiplap is a popular choice for homeowners because of its versatility—it comes in a variety of colors and textures and can be easily painted.

The main factors that influence the cost of your shiplap project include the type of wood, the project’s size, and what contractors in your area charge.

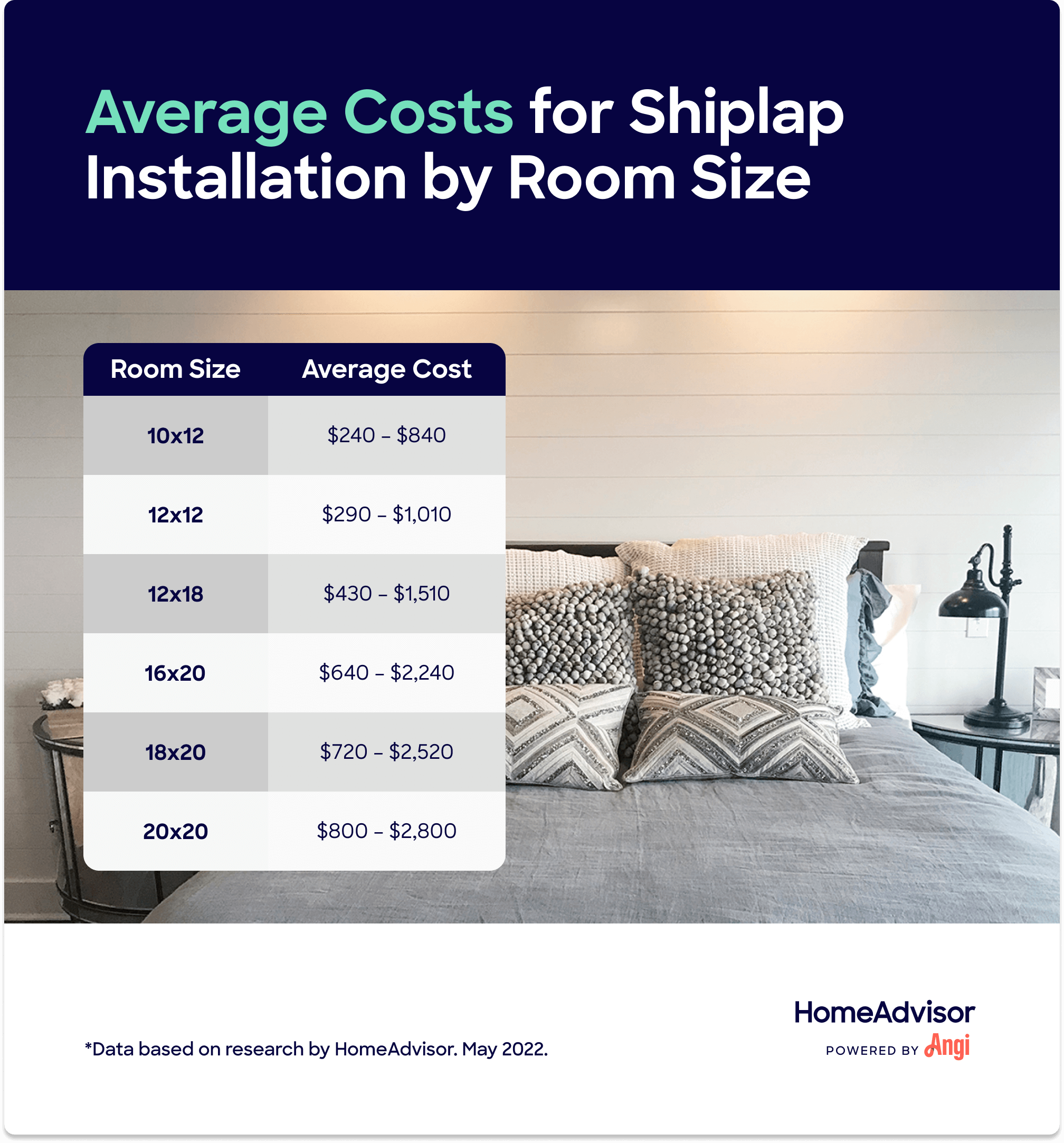

The cost to install interior shiplap is around $2.00 and $7.00 per square foot. Generally, interior shiplap is less expensive than exterior shiplap, and you may be able to get lower prices for larger projects when buying in bulk. For shiplap siding for a 1,000-square-foot home, the cost averages between $2,800 and $7,500. Below is a breakdown of how the cost varies with the square footage of the room you’re installing it in.

| Room Size | Installation Cost |

|---|---|

| 10x12 | $240 – $840 |

| 12x12 | $290 – $1,010 |

| 12x18 | $430 – $1,510 |

| 16x20 | $640 – $2,240 |

| 18x20 | $720 – $2,520 |

| 20x20 | $800 – $2,800 |

Professional carpenters charge between $35 and $100 per hour to install shiplap. Siding professionals usually charge between $1 and $4 per square foot to install shiplap on the exterior of a home.

Cedar, pine, and hardwood are the most popular types of shiplap and vary in price. Cedar usually costs between $2.50 and $7.00 per square foot, depending on the quality of the cedar. Pine averages $2.50 to $4.00 per square foot, and hardwood can run from $0.80 to $4.00 per square foot. Plywood is another option for shiplap and can be purchased in sheets and cut into several boards. Plywood sheets cost around $30 each.

Shiplap boards range in price from around $9 per board to upwards of $15 per board. The standard widths for shiplap boards are 5 1/4 inches and 7 1/4 inches. However, shiplap boards come in a wide variety of lengths and thicknesses. In general, the thicker and longer the board, the higher end of the cost spectrum the shiplap will fall into.

Unfinished hardwood shiplap is usually the least costly at around $8 per board, and primed and finished pine or cedar shiplap can run upwards of $20 per board. Shiplap pricing depends less on whether the board comes painted or stained and more on the type of board.

Below are cost estimates for the other materials you may need to install shiplap. The cost estimates are based on a 12-by-14-foot room (168 square feet). Pricing will vary depending on the store and how much of the material you need.

Underlayment: $75–$90

Nails: $2–$6

Spackle: $10–$20

Primer: $100–$125

Wood filler: $15–$20

Finish: $22–$26

Cladding (exterior shiplap): $2–$5 per square foot

Any additional accessories you choose to install, such as lighting or molding around the edges, will tack on costs. The costs for accessories will vary by type and materials.

Shiplap is a versatile material that you can install in most rooms in a home.

For bedrooms and living rooms, shiplap can work well as a statement wall. Alternatively, bring a new feel to the room by installing shiplap on all the walls. With all the different types of shiplap available, you have various colors and textures to choose from. You can even have furniture made with shiplap siding if you don’t want to do an entire wall but want to bring in an accent piece.

Shiplap is a good option for bringing a beachy feel to a bathroom. To protect your walls from moisture damage, choose a waterproof or water-resistant coating—such as polyurethane or Polycrylic—or use a coat of mildew-resistant paint to combat any mold growth.

Shiplap ceiling costs range from $2.50 to $7 per square foot, depending on your materials. Paneling your ceiling with shiplap can bring elegance and interest to a room. Shiplap has a more textured look than just plain drywall, and as an added bonus, you can use it to cover popcorn ceilings if you’re considering that option.

Horizontal shiplap is a common choice for pantry interiors. Shiplap can also be a unique choice for kitchen cabinetry or an accent wall. A shiplap backsplash adds texture to the area underneath your cabinets while not being too busy or distracting.

Some homeowners choose to install shiplap around their fireplace as an alternative to brick or stone. Shiplap is perfectly safe for use around fireplaces as long as you follow fire codes in your area. Tile, marble, brick, steel, and stone are noncombustible materials that you can install directly around the fireplace before installing shiplap.

A common rule for shiplap installation is that any combustible materials must be at least 6 inches away from the fire-box opening.

Shiplap is a popular choice for exterior siding, working as an alternative to aluminum, stucco, or drywall. While exterior shiplap is easy to install and resistant to the elements, it does have a few drawbacks. Shiplap can be harder to clean because dust collects in the grooves. The boards can warp or lift if installed improperly, and it’s costlier than drywall.

Shiplap, drywall, Sheetrock, tongue and groove, molding, and board and batten are all wall materials you can install in your home. Here are the costs of each of these wall materials for a 200-square-foot room so you can compare them with shiplap wall costs.

| Wall Treatment Material | Cost |

|---|---|

| Shiplap | $1,095 – $1,850 |

| Standard painted wall | $1 – $2 per square foot |

| Drywall | $1,000 – $1,200 |

| Sheetrock | $700 – $1,200 |

| Board and batten | $5 – $12 per sq. ft. |

| Tongue and groove | $2.50 – $3.00 per sq. ft. |

| Moulding | $4 – $15 per linear foot |

| Clapboard | $$1.90 – $3.00 per sq. ft. |

Sheetrock is actually a form of drywall and is a fairly common option that takes the place of plaster in walls. Drywall costs $1.50 to $3 per square foot, including materials and installation, while the cost to frame and build a wall is $2,000 on average.

While drywall and sheetrock are less costly and easier to paint than shiplap, shiplap can add a layer of visual appeal thanks to the intricate wood grain. In addition, shiplap is more durable than drywall or Sheetrock; it takes a significant amount of force to dent shiplap. Shiplap is also more moisture-resistant than drywall and Sheetrock, which tend to absorb moisture.

Tongue and groove siding usually costs between $2.00 and $3.50 per square foot. While shiplap uses rabbeted edges to connect the boards, tongue and groove planks interlock at the edges. The interlocking edges keep out the elements better than rabbeted edges.

In general, clapboard costs around $1.90 to $3.00 per square foot. Clapboard is less expensive than shiplap and uses thin, overlapping planks, which creates a textured surface. Both shiplap and clapboard are equally effective at protecting homes from exterior elements like wind and precipitation.

If you’re looking to add some visual interest to your room but don’t want to invest in shiplap, wood planking, wallpaper, or a paint pattern can be a good alternative.

When installing shiplap, homeowners should consider hiring a local siding contractor over DIY-ing. Aligning any sort of wood siding on the exterior of a home must be done with the utmost precision when it comes to measuring and cutting the boards; otherwise, you risk damage to your home. Interior wall installation also requires a high level of precision, especially when considering installing shiplap on a load-bearing wall. A pro will know how to check the home foundation, install the shiplap properly, and understand other structural elements to ensure their installation won’t cause damage.

Shiplap comes in a variety of price points. The most cost-effective form of shiplap is plywood, which you can buy in sheets for an average of $30 per sheet. From a pricing perspective, shiplap can be a bit more expensive than drywall. If cost is an issue, consider using shiplap as an accent wall and doing the other three walls with drywall.

You can install shiplap over drywall, but you should prep the wall before installing shiplap. A pro can nail shiplap into the studs to secure the base.

Either a local carpenter or siding company should be able to install shiplap, depending on whether your project is for the interior or exterior of your home.